WOOL2LOOP - the project

Geopolymer technology for the development of mineral wool waste value chains

WOOL2LOOP project solves one of the biggest challenges in the utilisation of construction and demolition waste by a new approach of circularity.

WOOL2LOOP provides new smart demolition and sorting technologies combined with a novel analysis method for mineral wool waste that enables separating the material based on its suitability for alkali-activation. Geopolymer technology, on the other hand, makes it possible to use mineral wool waste as a valuable resource for new ceramic or concrete-type products as pioneered by University of Oulu, Finland.

WOOL2LOOP project ended in November 2022. You can get to know the project by downloading the Final Report below.

Objectives

The overall objective of the WOOL2LOOP project is to divert mineral wool waste from landfilling and to develop its utilization into novel products, while securing the access to sustainable and non-conventional raw materials for the construction industry in the future.

From waste to valuable resource

A combination of smart demolition practices and on-site analysis will decrease the mineral wool waste separation costs to a level enabling reuse. Alkali-activation is a novel method to utilise mineral wool waste by converting it into ceramic or concrete-like materials.

Commercial utilisation of alkali-activated mineral wool waste

Alkali-activation technology has been successfully commercialised at several locations. The key aspect in commercialisation is the availability of raw materials. Mineral wool waste as a new raw material for alkali-activated materials would be an important addition to the market.

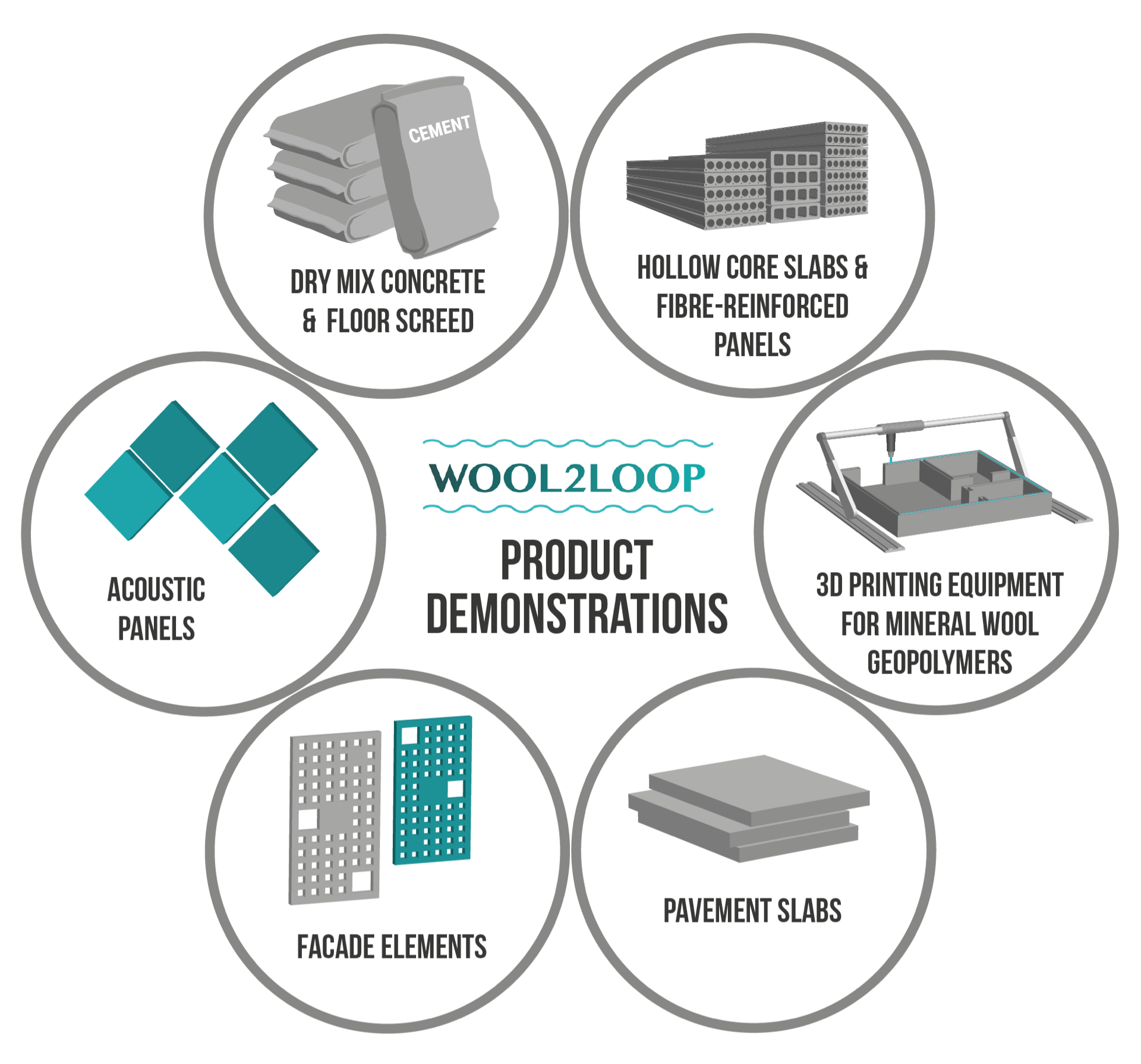

By careful mix design of mineral wool geopolymers, it possible to produce a wide range of value-added products with different properties.

Figure: Products of WOOL2LOOP demonstrations using alkali-activated mineral wool.

Want to stay in the know?

©WOOL2LOOP 2020